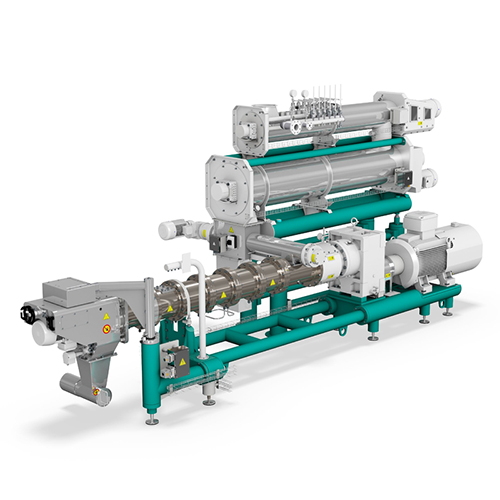

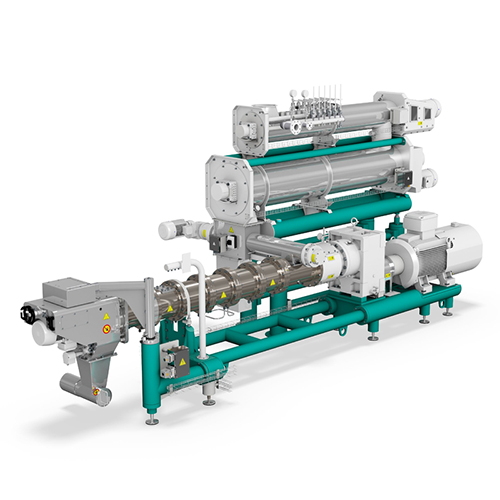

1. Single Screw Extruder2- Twin Screw ExtruderEXTRUSION

Polymer materials are very suitable due to their uses in many fields such as industry, engineering, etc. In the process of polyethylene extrusion polymer material similar to powder or granule is under compression, melting and transmission operation and on base of special form, extrudate has been produced. The equipment required for this process and producing granule from powder, is extruder. Extruders have different types. Twin-screw extruders are applicable in industries because of their high capacity. The powder mixing with chemical additives and melting with thermal and mechanical energy in three zones (feed, compression and metering zone) and because of gear pump and screw's pressure, converting to final product in latest plate. Extruders with twin-screw and short distance between screws are better than other types because of their high capacity and good thermal and mechanical stress. In this paper, process of polyethylene extrusion and various tapes of extruders are studied. It is necessary to have an exact control on process to producing high quality products with safe operation and optimum energy consumption. Therefore, all operation parameters like temperature and pressure, feed flow rate and grade in different conditions are considered and their relationships and diagrams are obtained. The granule size is depending on granulator motor speed. Results show at constant feed rate a decrease in granule size was found whit Increase in motor speed and relationships between HDPE feed rate and speed of granulator motor, main motor and gear pump are calculated.